Four classical damage models for concrete (three of which are available in commercial codes) have been compared and critiqued, showing that they all share the notions of a “teardrop” yield surface that can harden and (for some models) translate until reaching a three-invariant fracture limit surface that then collapses to account for softening (i.e., permanent loss of strength). Practical engineering models for rock and ceramics are similar. The common drawbacks of these models (primarily severe mesh dependence) can be mitigated, though not eliminated, by seeding their material properties in the simulation with spatial variability (aleatory uncertainty) and by using appropriate scale effects for the strength and failure progression properties. Continue reading

Tag Archives: simulation

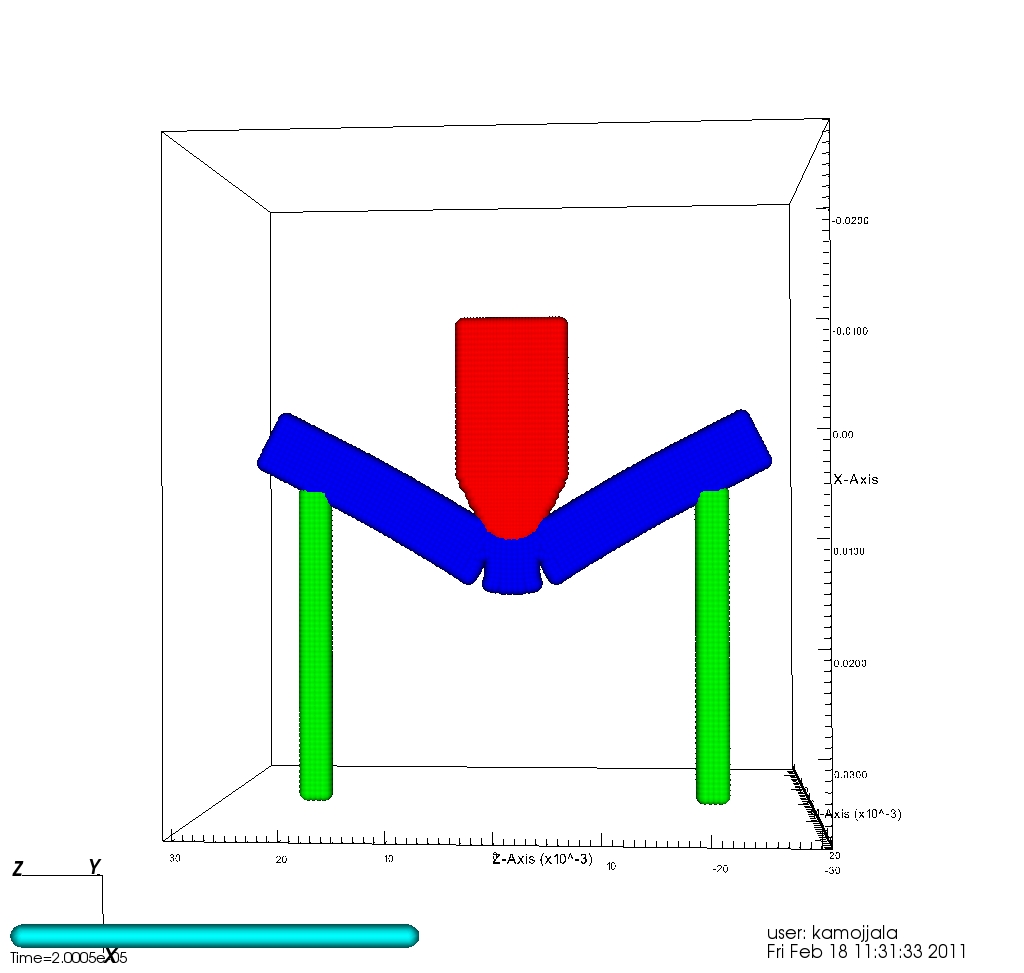

Powder metal jet penetration into stressed rock

The Uintah computational framework (UCF) has been adopted for simulation of shaped charge jet penetration and subsequent damage to geological formations. The Kayenta geomechanics model, as well as a simplified model for shakedown simulations has been incorporated within the UCF and is undergoing extensive development to enhance it to account for fluid in pore space.

The host code (Uintah) itself has been enhanced to accommodate material variability and scale effects. Simulations have been performed that import flash X-ray data for the velocity and geometry of a particulated metallic jet so that uncertainty about the jet can be reduced to develop predictive models for target response. Uintah’s analytical polar decomposition has been replaced with an iterative algorithm to dramatically improve accuracy under large deformations. Continue reading

Computational approaches for dynamically loaded low-ductility metals

Eulerian simulations of un-notched Charpy impact specimens, provide unsatisfactory results in that experimentally observed bend angle, absorbed energy, and fracture mode are not reproduced. The Utah CSM group is independently confirming poor simulation fidelity using conventional constitutive models. From there, we aim to identify the cause, and investigate solutions using capabilities in the Kayenta material framework.

UofU Contributors/collaborators:

Krishna Kamojjala (PhD student, Mech. Engr., UofU)

Scot Swan (MS student, Mech. Engr., UofU)

Tutorial: Radial Return

A tutorial on the underlying theory of projecting a stress state back to the plastic yield surface.

You may download the document here, or view just view the graph.

Tutorial: Mohr's Circle

A self-study refresher with interesting tidbits such as Pole Point and how to do Mohr’s circle for nonsymmetric matrices — very useful for quickly doing a polar decomposition! (Last posted 2003, but considerable work has been performed recently to incorporate Mohr’s circle as part of the opensource VTK for visualization in finite element simulations).

You may download the rest of the document here.