J.M. Wells and R.M. Brannon

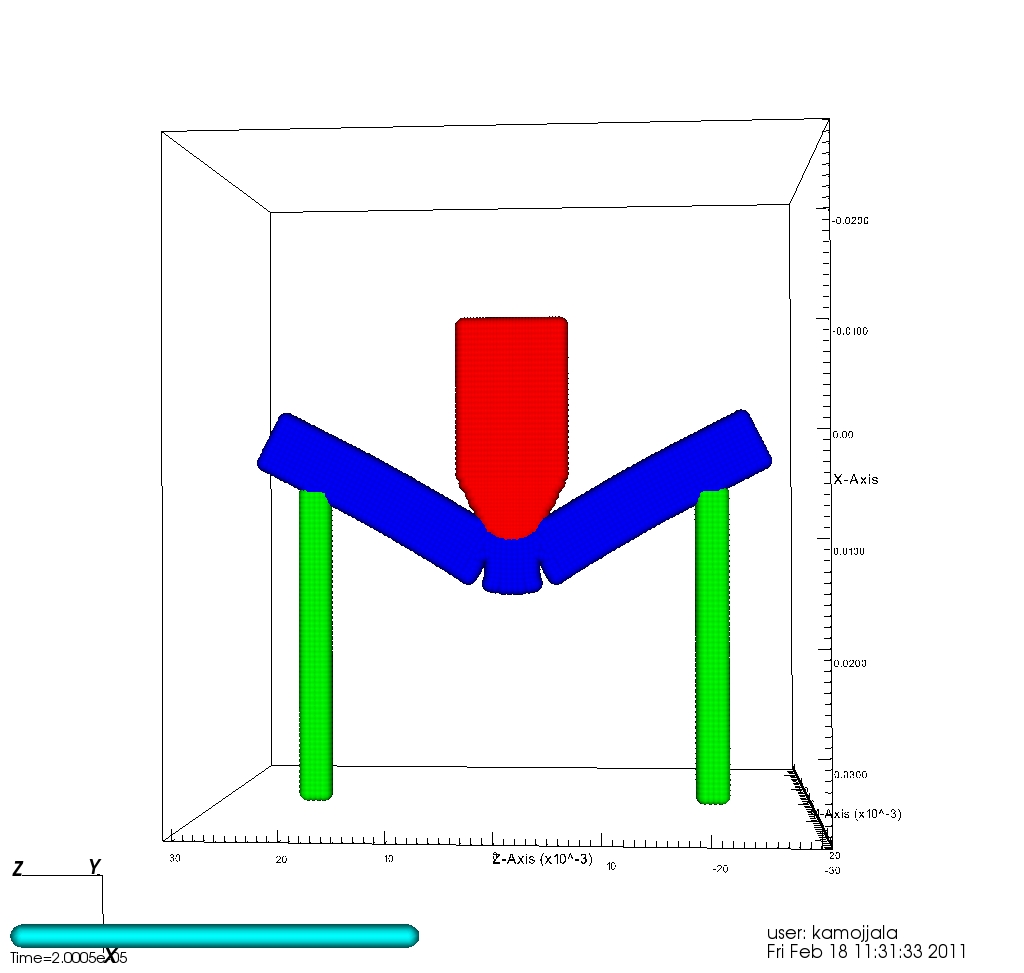

Dynamic indentation of SiC-N ceramic by a tungsten carbide sphere. Left: experimentally observed impact crater and radial cracking (both highlighted for clarity). Middle: BFS model prediction of externally visible damage. Right: prediction of internal damage (suitable for validation against XCT data).

With the relatively recent introduction of quantitative and volumetric X-ray computedtomography (XCT) applied to ballistic impact damage diagnostics, significant inroads have beenmade in expanding our knowledge base of the morphological variants of physical impactdamage. Yet, the current state of the art in computational and simulation modeling of terminalballistic performance remains predominantly focused on the penetration phenomenon, withoutdetailed consideration of the physical characteristics of actual impact damage. Similarly, armorceramic material improvements appear more focused on penetration resistance than on improved intrinsic damage tolerance and damage resistance. Basically, these approaches minimizeour understanding of the potential influence that impact damage may play in the mitigation orprevention of ballistic penetration. Examples of current capabilities of XCT characterization,quantification, and visualization of complex impact damage variants are demonstrated anddiscussed for impacted ceramic and metallic terminal ballistic target materials. Potential benefitsof incorporating such impact damage diagnostics in future ballistic computational modeling arealso briefly discussed.

Available Online:

http://dx.doi.org/10.1007/s11661-007-9304-5

http://www.mech.utah.edu/~brannon/pubs/7-2007WellsBrannonAdvancesInXrayComputedTomographyDiagnosticsOfBallisticDamage.pdf