Rim cracking of polyethylene acetabular liners and squeaking in ceramic components are two important potential failure modes of hip implants, but the loads and stresses that cause such failures are not well understood. Contact stresses in hip implants are analyzed under worst case load conditions to develop new wear testing methods to improve the pre-clinical evaluation of next-generation hip implants and their materials. Complicated full-scale hip implant simulator tests are expensive and take months to complete. A primary goal of this work is to find inexpensive surrogate specimen shapes and loading modes that can, in inexpensive lab tests taking only a few hours, produce the same wear patterns as seen in full-scale prototype testing. Continue reading

Category Archives: Projects

Nonclassical plasticity validation

Analysis and computations have been performed by the Utah CSM group to support experimental investigations of unvalidated assumptions in plasticity theory. The primary untested assumption is that of a regular flow rule in which it is often assumed that the direction of the inelastic strain increment is unaffected by the total strain increment itself. To support laboratory testing of this hypothesis, the general equations of classical plasticity theory were simplified for the case of axisymmetric loading to provide experimentalists with two-parameter control of the axial and lateral stress increments corresponding to a specified loading trajectory in stress space. Loading programs involving changes in loading directions were designed. New methods for analyzing the data via a moving least squares fit to tensor-valued input-output data were used to quantitatively infer the apparent plastic tangent modulus matrix and thereby detect violations of the regular flow rule. Loading programs were designed for validating isotropic cap hardening models by directly measuring the effect of shear loading on the hydrostatic elastic limit.

UofU Contributors/collaborators:

Michael Braginski (postdoc, Mech. Engr., UofU)

Jeff Burghardt (PhD student, Mech. Engr., UofU)

External collaborators/mentors:

Stephen Bauer (Manager, Sandia National Labs geomechanics testing lab)

David Bronowski (Sandia geomechanics lab technician)

Erik Strack (Manager, Sandia Labs Computational Physics)

Engineered microstructures for optimal energy absorbtion: design, validation, and verification

Breaking from conventional monolithic, layered, or woven designs for protective structures (bumpers, armor, etc.), micromanufacturing technology is now maturing to the point where precisely engineered microstructures may soon be possible. In anticipation of such advances, novel microstructures are being here designed to optimize the ability of protective structures to thwart impact loadings. Preliminary work shows that a variety of specially designed microstructures can distribute structural damage away from an impact site rather than allowing damage to be concentrated at the impact zone. The merits of these design concept are investigated numerically and experimentally in the scope of safety net design.

UofU contributors/collaborators:

S. Leelavanichkul (Research fellow, Mechanical Engineering, UofU)

A. Cherkaev (Prof. of Mathematics, UofU)

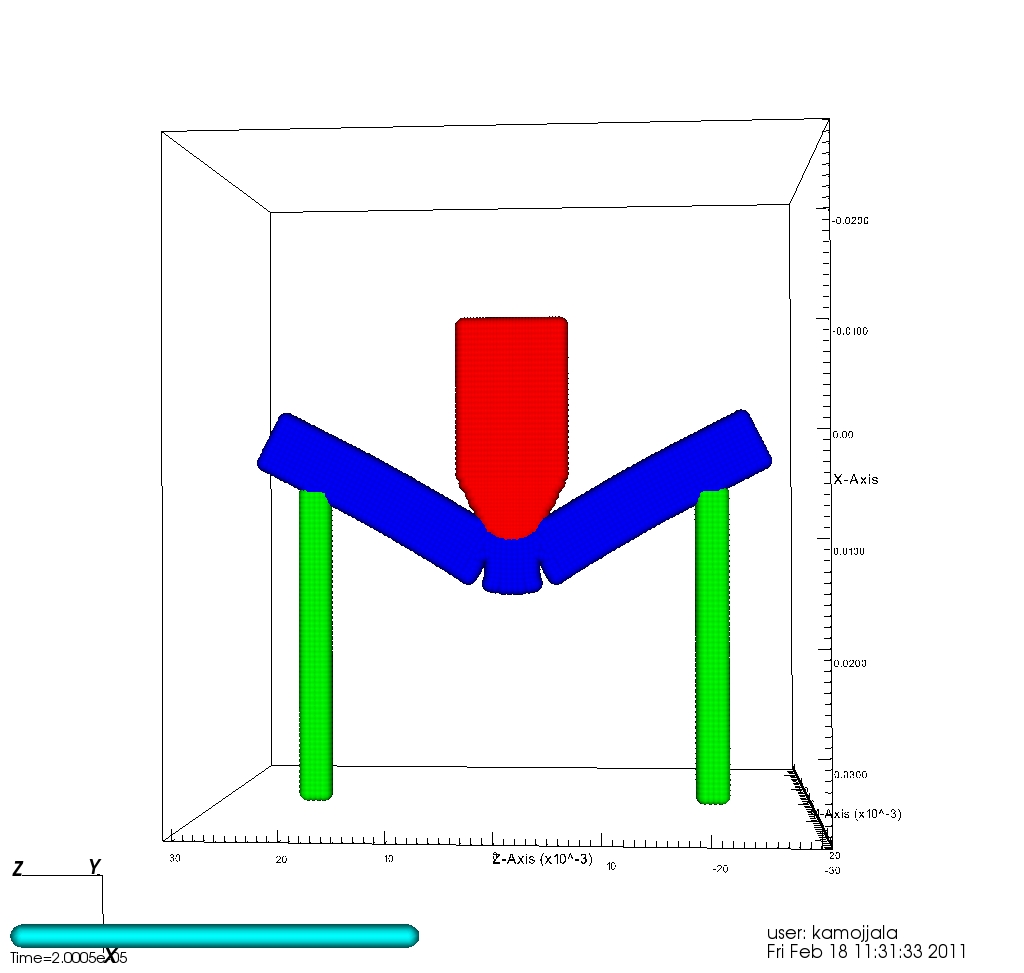

Computational approaches for dynamically loaded low-ductility metals

Eulerian simulations of un-notched Charpy impact specimens, provide unsatisfactory results in that experimentally observed bend angle, absorbed energy, and fracture mode are not reproduced. The Utah CSM group is independently confirming poor simulation fidelity using conventional constitutive models. From there, we aim to identify the cause, and investigate solutions using capabilities in the Kayenta material framework.

UofU Contributors/collaborators:

Krishna Kamojjala (PhD student, Mech. Engr., UofU)

Scot Swan (MS student, Mech. Engr., UofU)

Publication: Assessment of the applicability of the Hertzian contact theory to edge-loaded prosthetic hip bearings.

Sanders, A. P. and R. M. Brannon (2011). “Assessment of the applicability of the Hertzian contact theory to edge-loaded prosthetic hip bearings.” Journal of Biomechanics 44(16): 2802-2808.

Abstract

The components of prosthetic hip bearings may experience in-vivo subluxation and edge loading on the acetabular socket as a result of joint laxity, causing abnormally high, damaging contact stresses. In this research, edge-loaded contact of prosthetic hips is examined analytically and experimentally in the most commonly used categories of material pairs. In edge-loaded ceramic-on-ceramic hips, the Hertzian contact theory yields accurate (conservatively, <10% error) predictions of the contact dimensions. Moreover, the Hertzian theory successfully captures slope and curvature trends in the dependence of contact patch geometry on the applied load. In an edge-loaded ceramic-on-metal pair, a similar degree of accuracy is observed in the contact patch length; however, the contact width is less accurately predicted due to the onset of subsurface plasticity, which is predicted for loads >400N. The Hertzian contact theory is shown to be ill-suited to edge-loaded ceramic-on-polyethylene pairs due to polyethylene’s nonlinear material behavior. This work elucidates the methods and the accuracy of applying classical contact theory to edge-loaded hip bearings. The results help to define the applicability of the Hertzian theory to the design of new components and materials to better resist severe edge loading contact stresses.

Available online:

http://dx.doi.org/10.1016/j.jbiomech.2011.08.007;

Verification Research: The method of manufactured solutions (MMS)

MMS stands for “Method of Manufactured Solutions,” which is a rather sleazy sounding name for what is actually a respected and rigorous method of verifying that a finite element (or other) code is correctly solving the governing equations.

A simple introduction to MMS may be found on page 11 of The ASME guide for verification and validation in solid mechanics. The basic idea is to analytically determine forcing functions that would lead to a specific, presumably nontrivial, solution (of your choice) for the dependent variable of a differential equation. Then you would verify a numerical solver for that differential equation by running it using your analytically determined forcing function. The difference between the code’s prediction and your selected manufactured solution provides a quantitative measure of error.

Reciprocating edge-load wear test of artificial hip bearings

Movie: edge load wear test of hip prostheses

This short movie shows a novel wear test for artificial hip bearings. This test focuses on what may be the most severely damaging scenario that artificial hips experience in the human body. In some patients, the hip joint may partly separate under certain circumstances, and when that happens, the typically congruent contact between the ball and socket can quickly become a non-conforming contact between the ball and the socket’s edge. In that scenario, the contact between the ball and socket has the potential to cause increased wear, because the contact stress is much greater.

The test apparatus applies a horizontal load to the femoral head (the ball), which forces the head into contact with the socket’s edge. Meanwhile, the acetabular liner is reciprocated up and down at a rate of 1 cycle per second. Several aspects of the test set-up may be configured as desired, including the magnitude of the horizontal force, the orientation of the acetabular liner, and the speed of reciprocation.

This test method is yielding valuable information about the performance of artificial hip bearings under worst case conditions. The findings of several focused studies will be published in the scientific literature relevant to the field of orthopedic implants and joint arthroplasty.

Animation showing set-up of femoral head reduction test

Animation: Biomechanical reduction test set-up

This short animation illustrates the set up of a femoral head reduction test. The items shown – a femur, a femoral stem with a femoral head, and an acetabular liner – will be tested in a manner that simulates the instantaneous reduction that occurs to a subluxed femoral head upon heel strike during human gait.

Publication: Experimental Assessment of Unvalidated Assumptions in Classical Plasticity Theory

Abstract: This report investigates the validity of several key assumptions in classical plasticity theory regarding material response to changes in the loading direction. Three metals, two rock types, and one ceramic were subjected to non-standard loading directions, and the resulting strain response increments were displayed in Gudehus diagrams to illustrate the approximation error of classical plasticity theories. A rigorous mathematical framework for fitting classical theories to the data, thus quantifying the error, is provided. Further data analysis techniques are presented that allow testing for the effect of changes in loading direction without having to use a new sample and for inferring the yield normal and flow directions without having to measure the yield surface. Though the data are inconclusive, there is indication that classical, incrementally linear, plasticity theory may be inadequate over a certain range of loading directions. This range of loading directions also coincides with loading directions that are known to produce a physically inadmissible instability for any nonassociative plasticity model.

You may download the full report here.